As published in Elevator World Magazine – Mar 23

A discussion about a sometimes-overlooked component of elevator maintenance

For more than 46 years, Patrick Morrissey (PM) has led ConSpec Associates Inc., based out of his home in East Haven, Connecticut. Morrissey’s involvement with engineering and construction dates back to the 1960s, when he earned a BS in civil engineering from Manhattan College, followed by work on a master’s degree in concrete and construction management from the New Jersey Institute of Technology. As a past longtime director of associations, including the International Concrete Repair Institute and Association for Preservation Technology, based in St. Paul, Minnesota, and Springfield, Illinois, respectively, Morrissey ascribes to the “SIP vs ROAR” philosophy, which favors stabilizing in place (SIP) over the rip out and replace (ROAR) approach for preserving the built environment.

Morrissey formed ConSpec in 1976 to “combine technology with tradition in both methods and materials for innovative, cost-effective, engineered solutions for the restoration, maintenance and repair” of structures. For many years, his concentration was on concrete, but exterior, as well as speed tile interior and concrete masonry units (CMUs) (materials used for elevator shafts) became more of a focus. After customers of Champion Elevator asked Champion President Don Gelestino (DG) for help with elevator shaft repair, he referred these customers to Morrissey and ConSpec since this is out of Champion’s realm of expertise.

Approximately 11 years ago, Morrissey learned about a product called RUREGOLD, which he says is a “logical solution” for elevator shafts. It is a fiber-reinforced concrete matrix (FRCM) material and process developed in Italy more than 20 years ago for both the stabilization and strengthening of historic masonry structures. Elevator specialists, both contractors and specifiers, typically do not address elevator shaft walls — only the mechanical, electrical and aesthetic (as well as, of course, performance) aspects of a job, Morrissey says. So, when it comes to shaft wall issues, ConSpec is ready to help. As one of Morrissey’s colleagues puts it, “Being a masonry restoration firm in NYC, elevator shaft restoration is now part of the company’s DNA.” Both active members of the NYC construction industry, Morrissey and Gelestino have collaborated on major elevator jobs over the past several years. They took time to speak with your author (KW) about the niche business of elevator shaft repair and stabilization.

KW: How big of a role does masonry play in elevator shaft maintenance, and what is the proper procedure for its “care and feeding?”

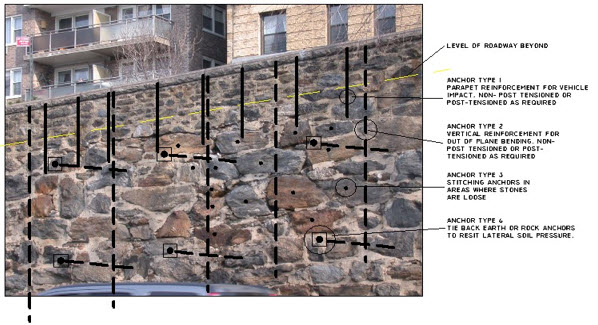

PM: Masonry is the primary wall “shaft” material and, as such, a key factor in most rehabilitations. Its “care and feeding” has only recently being recognized as crucial.

KW: Is it safe to say asbestos abatement is the top reason for elevator shaft plaster replacement? What would be other reasons?

PM: Asbestos abatement is a major reason, but instability, cracking and partial failures that may cause an elevator shutdown are becoming more frequent, and localized problems can occur — both scheduled and emergency.

DG: In this case, it is very important to be proactive versus reactive. Any number of NYC Department of Buildings (DoB) inspectors, third-party witness company inspectors, elevator consultants or even the elevator company itself can open an asbestos claim in which the shaft way may be deemed contaminated. Then, the elevator system itself may be deemed unusable.

KW: What would be the approximate pricetag for an elevator shaft asbestos abatement project?

PM: On one recent project, the materials alone to replace the asbestos-laden plaster were US$650,000 — and that was for only three shafts. Add to that the labor for removing the asbestos, and replacing, stabilizing and strengthening the shaft walls (as required by code) and that number will be considerably higher. Proper inspection and planning are, therefore, extremely important to consider to minimize exposure and expense.

KW: Describe the typical makeup of elevator shaft walls.

Elevator machine room ceiling damage

PM: Elevator shaft walls are made up of many different materials, including plaster block, masonry and drywall, depending on when the building was constructed. Whether a structure is a private townhouse or commercial high rise, the problems are similar. Two projects currently underway in NYC involve as little as 3,000 ft2 for a rowhouse and as much as 100,000 ft2 for only three shafts in a commercial high-rise tower undergoing asbestos abatement.

KW: Could you provide an example in which shaft walls became an issue for a property owner?

DG: Sometimes, they can become a major issue. There was a facility installing raceway — an enclosed channel designed for holding wires, cables or bus bars[1] — in the hallways of a

30-story building. The anchors used caused penetration into the elevator shaft. Debris was sent down into the shaft and onto the elevator cartop. This situation became a “reactive” one, and also warranted further investigation into the shaftway materials. This, in turn, caused immediate, unexpected elevator downtime.

KW: How frequently does Champion recommend having elevator shafts surveyed to prevent this?

DG: Elevator shaft surveys should be mandatory once every three to four years, as shaft conditions can change due to water penetration, vibration, nearby construction projects and other environmental conditions. Elevator machine room walls and ceilings have encountered similar issues, which can cause debris to fall onto and into equipment. These spaces should also be inspected. Performing such surveys is a proactive approach that can help a property owner or manager properly capital plan for remedial projects, rather than be surprised.

KW: How important is planning?

PM: Planning is extremely important, as having a shaft out of service can be a very serious matter, especially in a single-shaft building. Even worse is when a shaft is shut down unexpectedly due to the shaft wall surface hitting the top of the cab and having the elevator shut down by the DoB. Should a piece of masonry or plaster separate from the shaft wall due to fatigue, construction defects or wall penetrations, those dislodged pieces will fall and hit the cab ceiling, causing a shutdown for safety pending remediation.

Damage caused by improper anchor installation

KW: What should a property owner’s first consideration be when considering hiring a masonry restoration consultant?

PM: Time is of the essence. Having a plan of action in place provided by a masonry restoration consultant will determine a property owner’s exposure in both downtime and cost. Consideration should also be given to whether there should be any seismic upgrades performed during a restoration project. This can be particularly expensive if the proper methods, means and materials are not in place. Few elevator companies and consultants address masonry, so the building owner needs a masonry restoration consultant that goes beyond providing specifications for the façade to include elevator shafts.

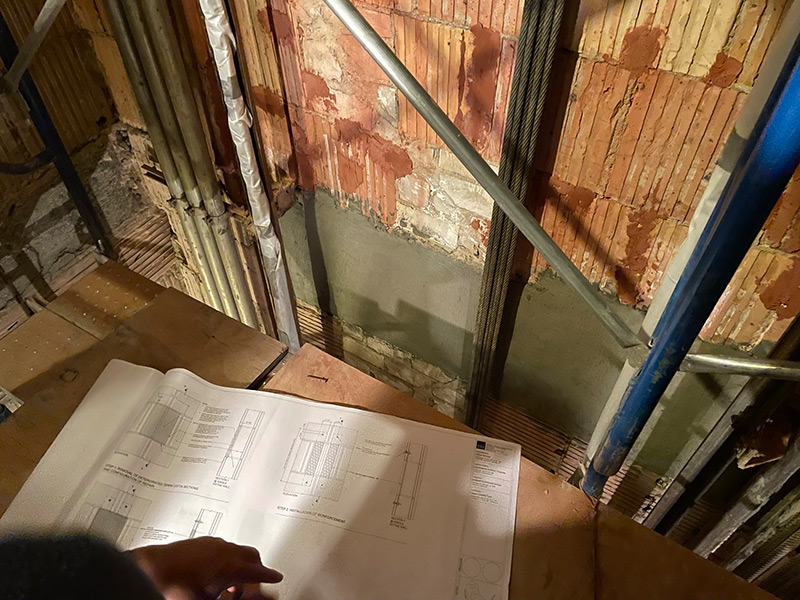

KW: How is this type of work particularly targeted to elevator shafts?

PM: Elevator shaft resurfacing with structural stucco, while straightforward in itself, has unique conditions and requirements, such as confined space, a movable work platform, obstructions and just overall difficult working conditions. Most masonry contractors, while proficient in façade renovation, are not set up to handle the typical masonry required for elevator shafts.

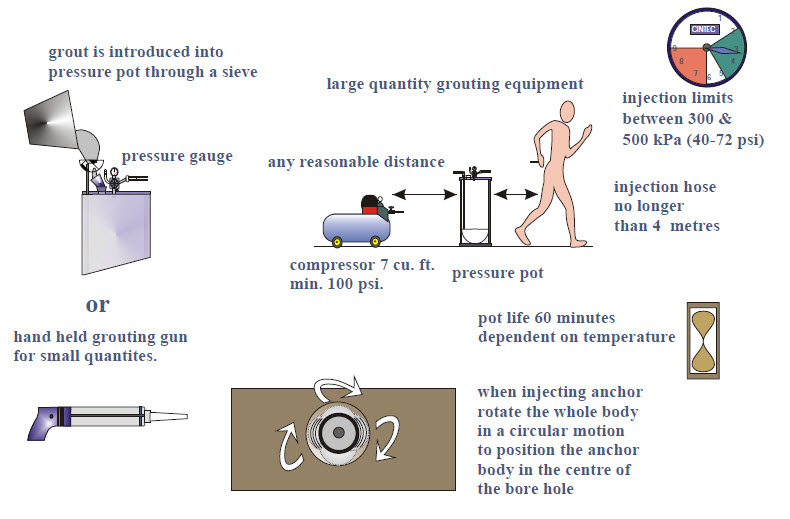

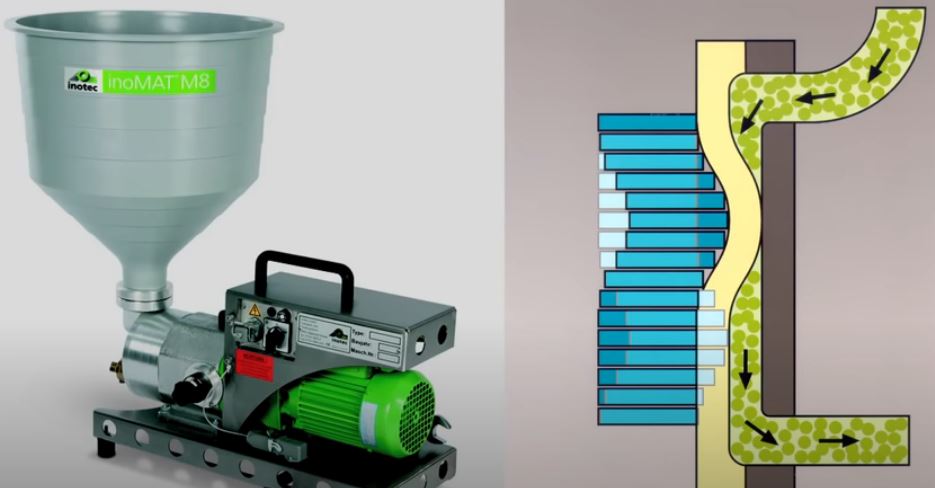

KW: What are ConSpec’s preferred process and materials for elevator shaft modernization?

PM: We use RUREGOLD because it is a structural stucco that is as easy to apply as traditional stucco, breathable, code-approved, has a Class A fire rating, no odor and provides a ductile failure, unlike other systems that are brittle and inappropriate for this application. The two projects previously mentioned are using this system. However, it is good only for masonry, like CMUs (also known as architectural blocks) and Speed Tile. It will not work on plaster or drywall.

KW: How does the RUREGOLD process work, and could you provide an example or two?

PM: For FRCM, a correctly protected elevator roof is used as the access platform. The remaining shaft and elevator equipment is properly protected, and RUREGOLD is applied over deteriorated surfaces. By providing “structural stucco” to deteriorated surfaces, the application facilitates fast project completion and optimum repair results. One of our recently completed projects was an elevator shaft in a historic, 140-year-old building in downtown NYC. The scope of work included application of FRCM over the existing, deteriorated CMU walls to achieve structural stability within the shaft. Our work crews applied RUREGOLD at specified areas following precise manufacturer instructions and conducted multiple team visits to confirm desired performance. The project was completed on time, within budget and with minimal disruption to building operations.

KW: What other services does ConSpec related to elevators?PM: Elevator pit waterproofing is another aspect of elevator shaft maintenance we get involved in, as contractors that provide this service are, often, the same contractors that will provide the application of RUREGOLD to the shaft walls since they are masonry contractors, as well.

DG: This great technology has helped many property owners save thousands of dollars over the years. It is a blessing to see equipment that went through years of water damage have no more issues. From my perspective, it’s a mini miracle!

KW: What is your outlook for this niche business?

PM: As with any maintenance, it is only a matter of time before issues become more frequent and serious enough to be addressed. As to the size of the market, the Thurgood Marshall U.S. Courthouse (in Lower Manhattan) — only one project — represents several million dollars. So, the overall market is quite significant.

Water-damaged shaftway before repair

Water-damaged

shaftway after repair

Reference

[1] Holt, Mike. “Understanding Raceways,” EC&M, February 13, 2018.